Although

pixels look small, they make big impacts when it comes to diagnostic imaging. A

pixel’s duty is to receive the beam electrons and then later transfer the data

and form an image or a radiograph. If

there are a lot of non-functioning pixels in a detector, it would greatly decrease

the quality of the image. Each pixel contains a unique data that other

pixels cannot be replaced and that is why pixel’s condition is so important. It is important to check every 3 to 6 months

to see if all the pixels are still functioning normally. Otherwise, dead pixels

would show up as artifacts or white dots and other technologists might think it

is an actual artifact and might lead to an unnecessary repeat.

Since pixels play such a big role, I think it is important

to maintain it quality. A Quality

Assurance Procedures, or formerly known as QAP is the only way to test if there

are any dead pixels in a detector. As mentioned above, too many dead pixels

will decrease the quality of the image because the dead pixels will appear

white and shown as artifacts. Having

such artifacts will affect the result of diagnosis because the artifacts might

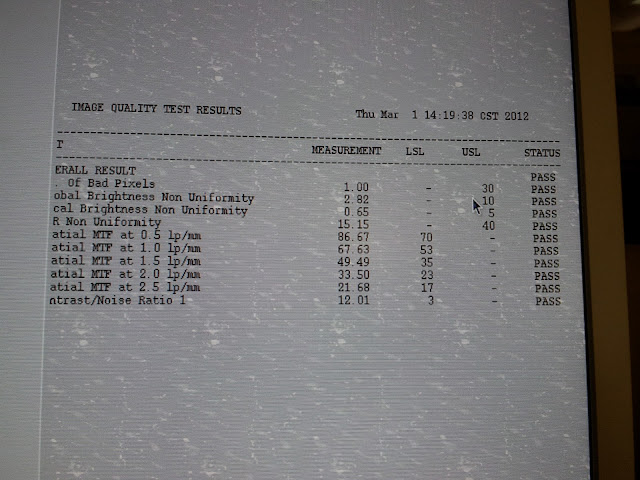

be on the exact same spot of pathology. Each manufacturer has a different acceptance

range of bad pixels. According to GE, the manufacturer of our machine, the pass

or fail depends on the number of dead pixels. Here is our test result.

As seen above, there was only one dead pixel and we passed

the image quality test. We should keep track of each month’s QAP to see if

there are any more dead pixels, because eventually, the dead pixels would

accumulate and fail the quality assurance test.

If we do not perform any QAP, the dead pixels will gives us troubles

during our labs because of the numbers of the dead pixels. This is another

reason why quality control should be carried, so that the equipments are kept

at high quality and utilize itself.

No comments:

Post a Comment